Taking out the tempeh sheets from the freezer, I suddenly realised that they became much less flexible and easier to break. It would really help if tempeh sheets can be unpacked right after taking out of the incubator, when it is still fresh and flexible. Once it gets frozen, it loses it tenacity.

Tempeh Sheet 1 layer frozen directly got crispy -

The sheets can be seen as product material, and definitely, also cooking ingredients. Preparing the shapes in the kitchen, using kitchen knife to cut them, looks more than natural.

Tempeh Sheet frozen ready to be cut in the kitchen -

Tempeh Sheet Material is very easy to cut after frozen -

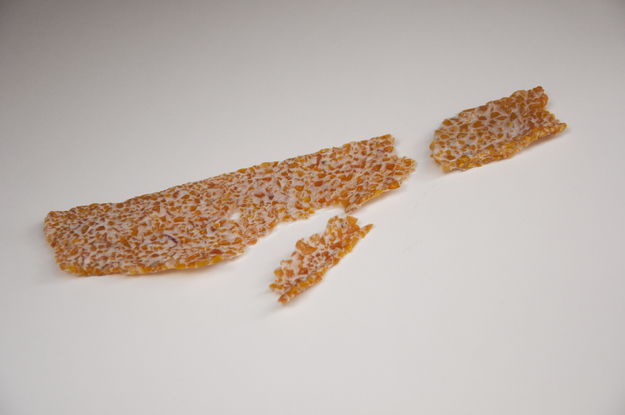

It proved that tempeh sheets after freezing are very easy to cut neatly with a kitchen knife. Several forming techniques are used: cutting into a certain shape, bending a stripe along a metal ring, and forming several stripes inside a bowl. While bending, the material is easy to break, because it has been frozen. These shapes are sent into a dehydration machine, just to dry out and fix their forms.

After frozen tempeh sheet is really easy to break -

Tempeh stripes inside a bowl to form -

Different Shapes of Tempeh Sheets in the dehydration Machine -

At first the temperature was set at 80˚C because I wanted the drying time to be shorter. After 1 hour, I found the temperature too high because some thin parts started to break. So I lowered the temperature to be around 55˚C. An hour and a half later, Most of the pieces were completely dried out, some were even a bit over dried. The 1 layer sheet materials broke very easily.

Broken Circle Tempeh Sheet (1-2 layers of lupins) after drying -

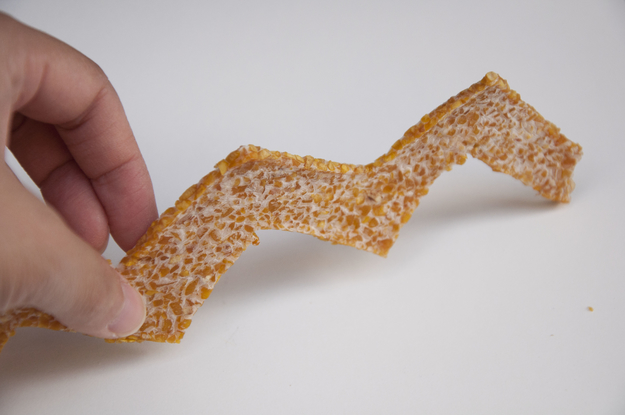

The 2-3 layer material of a zigzag shape was intact, however still fragile.

The material in the bowl shape was heated so unevenly that on the edge it broke easily while in the middle it was still wet.

Easy to break on the outer part of the bowl shape -

This kind of mould is dries unevenly, convex part is still wet -

The mould test also showed that the sheet material can be moulded by bending along a certain mould.

Tempeh Sheets shape can be changed by drying process on a certain mould -

However, the stripe on the metal ring broke down completely, because it stuck to the metal surface. Maybe in the future, a thicker material should be used and also removal agency should be used, such as oil.

Tempeh Sheet breaks when taken off the moud -

Tempeh Sheet off Metal Mould Needs Mould Remover -

Playing with the only completely piece- the zigzag shape, was kind of inspiring, because it suddenly invoked different ways of using this piece.

Play with zigzag tempeh sheet 1 -

Play with zigzag tempeh sheet 2 -

Play with zigzag tempeh sheet 4 -

Play with zigzag tempeh sheet 3 -

The next step is to find a proper thickness of fresh tempeh sheep and mould it properly to avoid sticking to mould and dry it properly without over heat.