The 3D Print Canal House is an exhibition, research- and building site for 3D Printing Architecture. A unique project where an international team of partners collaborates in ‘research & doing’ linking science, design, construction and community, by 3D printing a canal house at an expo-site in the very heart of Amsterdam. What makes the 3D Print Canal House special is that it is a project which is 'open' in every way: The initiators, designers and builders (DUS architects) are the client: the focus is on research, experimentation and development, instead of finishing a house.

Found on website of 3D Print Canal House

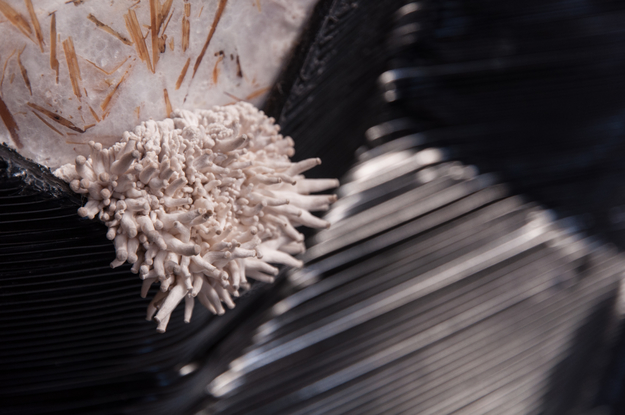

Together with DUS architects, our intern, Rob van der Burg tried to insulate a piece of the 3D Printed Canal House. He did this by filling the piece with a substrate (straw) and infected it with mycelium of the oyster mushroom. The mycelium starts to grow and in this way it 'glues' all the straw together. When it's fully grown, the mycelium insulates the piece. On larger scale it will insulate the entire canal house.