Material philosophy

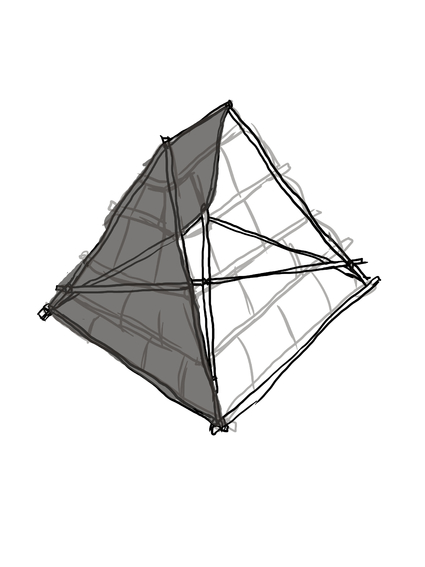

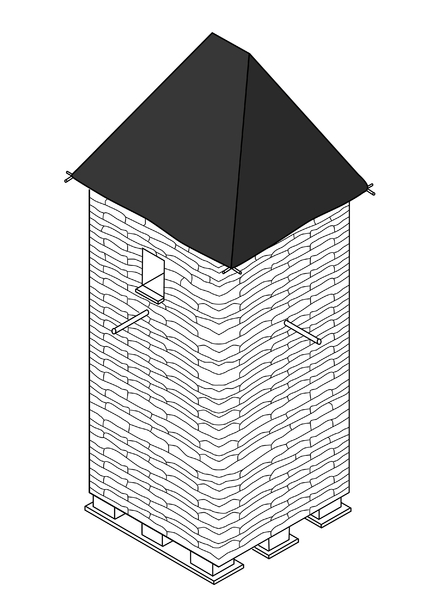

The straw and mycelium blocks, that we use to build the tower, are fragile standing alone, which makes it difficult to construct a roof. The first attempt was made of willow and tarp. Josef has also been working on a roof from plywood. The last was quite heavy and maybe too perfect. Not the right fit for the living tower. So the search continues. In line with the philosophy of the tower, the preferable material would be “green” or “set-aside”. And with “set-aside” I mean material that is used before but doesn’t have a fixed purpose anymore. It is already laying around in an attic or ready to be thrown away.

When you work with mycelium you learn to listen to what the material has to say, and respond to that. You need to work slowly and build with care. Whether the material grows together or not, depends on how you treat it. The mycelium grows mostly on the surface, so when this surface damages we often speak of “breaking the skin”. After all we are working with a living material. With the motto “Learn to listen what the material has to say” in mind we looked again at the material, noticing a potential roof-material laying right under our noses.

From Packaging...

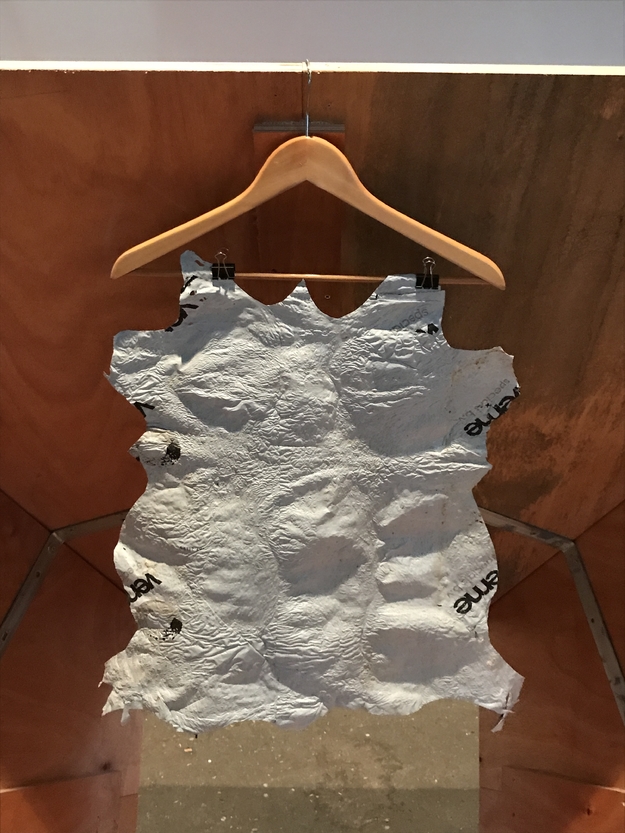

The mycelium is grown in plastic bags, because it is easy to cut through. This enables the mushroom growers to control mushrooms growth. We cut open these bags to get to the mycelium, the “meat”, which we build with. When you look again at the materials traveling through the cycle of the mycelium (pigeon) tower, one material leaves unnoticed. Stripped of the meat the plastic bags are leftover, or “set-aside”.

To Beaver Skin

The great benefit of plastic is that it is waterproof, easy to bend, adjust and repair. Ideal for a roof. Because the bags have holes and are thin, they melt under quite a low temperature. With an iron, for instance, you can melt the thin layers of plastic just enough to stick them together. We were surprised to discover air bubbles forming on the surface while heating. This uncontrollable shrinking and bubbling resulted in a leather- or skin-like surface. It is strange to notice how this association changed the value of the material. And the role it is playing within the project cycle.

Using plastic bags as building material - Drying the plastic

The Plastic Tannery

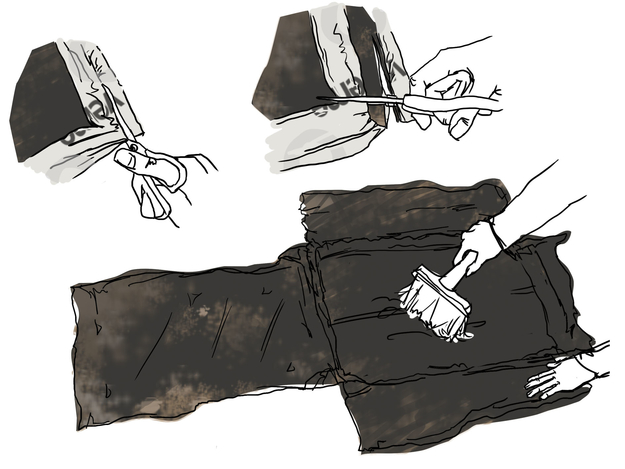

Before you can use the plastic, you need to cut the bag open to get the “meat”, the mycelium, out. After the skinning, the corners of the bag need to be cut open to lay the plastic out flat. Large pieces of mycelium are removed with a brush and the cleaned bags are hanged to dry. When dry, every bag is cut in pieces, ready for the iron.

How to use plastics to build a roof for the mycelium tower - Handling the plastic / skinning

How to use plastics to build a roof for the mycelium tower - Clean the plastic

How to use plastics to build a roof for the mycelium tower - Hang to dry

For the ironing, the plastic layers are stacked in between two sheets of baking paper. With the iron on the highest temperature, you slowly move over one side of the baking paper. When that side is hot, you place a weight on top and move to the other side. After making sheets of different thicknesses, we believe that 6 layer sheets are the best fit for the roof, since the sheets are strong yet flexible.

Folding Tiles

Now we are making a roof where we cut the sheets of thicker plastic into roof tiles. Josef is working on a willow frame, where the roof tiles can be folded around. It is still a challenge to prevent the lightweight tiles from blowing up. Maybe the flexible tiles could be woven through the construction, almost like thatched roofs. Let’s try it out and see. One last beautiful detail that comes with the ironed roof tiles is the granite look. Because the bags are black on the inside and gray on the outside with a logo and additional information, they turn into black granite tiles with shards referring back to its history.

How to use plastics to build a roof for the mycelium tower - Roof Construction