We've made 4 new panels, along with some changes to our growing approach.

Some of the lows from previous experiments:

Panels drying out, during incubation.

Panels were showing primordiums - ''Baby Mushroom¨ growth, a stress response to light and drop in temperature.

Positive changes we have made:

We suspect the drying out was due to too much air around the panel (inside).

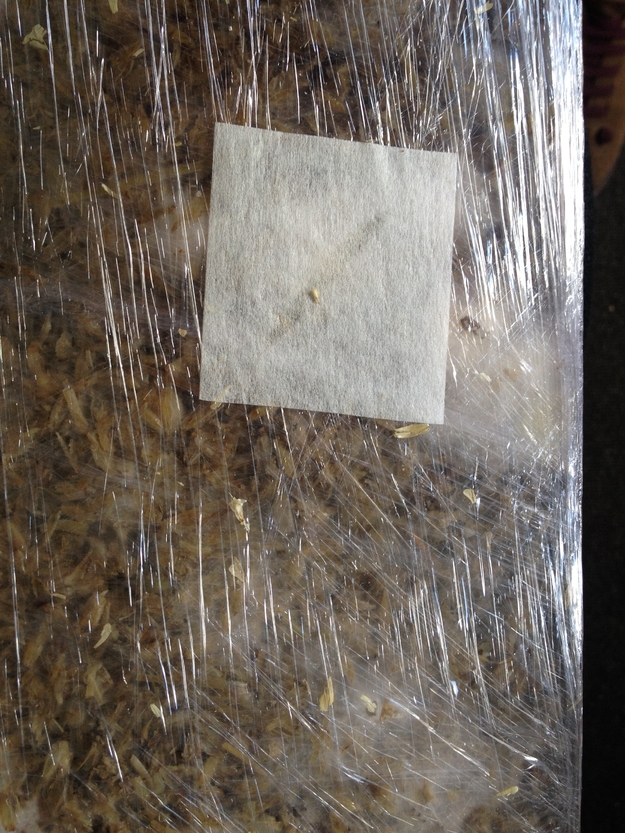

Our solution Panel#5 - Wraping the panel covering the panel with plastic wrap for a successful growth

The new panels are completely jam packed with substrate and Jute sack, and tightly wrapped to the top.

This was only possible after angle grinding off the metal rims that curled inside (thank you Sim). Now the substrate is flush to the rim, with minimal air space. Small cuts were made on the top, now covered with 'filter tape'.

So goodbye cotton wool clouds! Lets see how well they retain moisture now. Also no more injecting the panels with water. This eliminates chance of infection.

To minimise primordiums sprouting while growing the mycelium, we have improved the incubator by blocking out most light.

First new panel (#5): 4th May 2015

The substrate (Husks 600g) and Jute sacks, after being sewn with rope, were pasteurized by immersion in water, for 1 hour at 100c.

The pasteurized husk substrate and Jute sacks, were left to cool down. After which, were inoculated with Schizophyllum on Rye Grain spawn (60g). 10 percent of the 600g substrate. To finish, the panel was tightly wrapped, and given 'breath holes' using the filter tape. Moved to dark incubator at 30c.

Spawn Making

We may start using Millet instead of Rye grain for spawn making. Both the millet and the rye grain spawn we make here, are still sterilized, because the rye contains nutrients and starch which will still attract other organisms if not sterilized. Where as the Husk substrate we can now pasteurize instead, saving energy!

Pasteurization & tea bagging Pasteurising - We are pasteurising the Substrate and the Jurte together for 1h.

When pasteurizing our husk substrate, it needs to be well drained, and cooled before we can inoculate it. So we tried filling a pillow case with husks and a single ladies tight.

The tight worked a treat! very easy to remove from the water, and even easier to rinse, dry and cool. The Pillowcase didn't work because it retained a lot of water.

New Panels, 2,3 & 4: 11th May 2015 Pouring substrate to panel 5 - Substrate on Panel scattering inoculated substrate on panel

The same preparation and method was used for pasteurization of husk substrate, and jute sacks. Cool down. Inoculate. Wrap, and make filter holes with filter tape. Store in Incubator at 30c.

With these panels we tried different Stretching methods, by sewing the rope in different ways.

Panel 2: 100g Yellow Oyster on rye grain, onto 500g pasteurized husk substrate.

Panel 3: 70g King Oyster on rye grain, onto 600g pasteurized husk substrate.

Panel 4: 56g SPOPO Grey Oyster on millet, onto 600g pasteurized husk substrate.

Let the growing Commence!